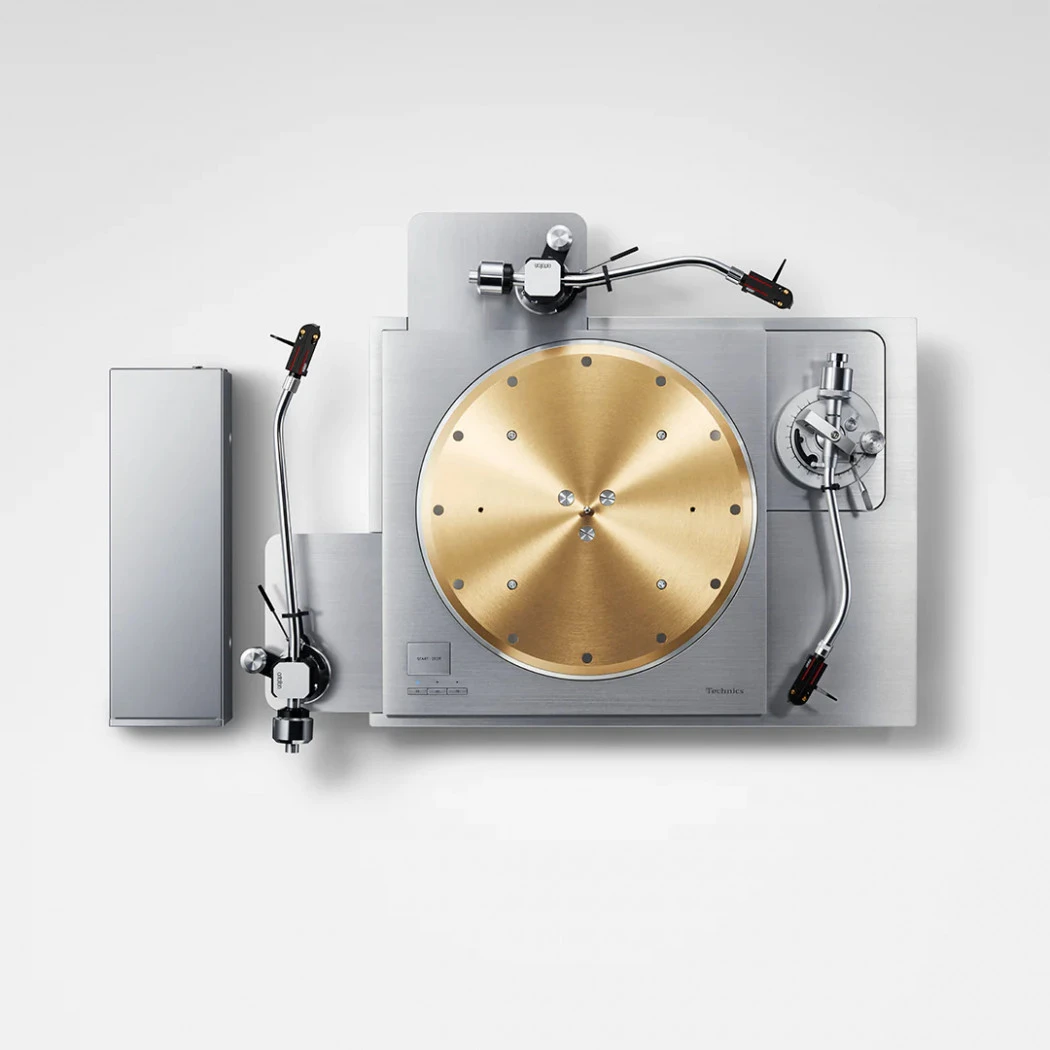

Technics SL-1000R Reference Class Direct Drive Turntable System

$390.00 Original price was: $390.00.$95.99Current price is: $95.99.

- Get the Best for Less

- Buy with confidence, backed by quality.

- Quality and Affordability Combined

- Excellent customer service online in a timely manner

SL-1000R

Reference Class Direct Drive Turntable System

Coreless Direct Drive Motor

based on the coreless direct drive motor that was developed for the

SL-1200G launched in 2016, and further improved. The double coil twin

rotor-type coreless direct drive motor that was newly developed for this

purpose had coils on both sides for 12-pole, 18-coil drive, with high

enough torque to drive the heavyweight-class platter (approximately

7.9-kg). Offsetting the coils on both sides 60 degrees improved the

rigidity of the substrate, suppressing fine vibrations and reducing

self-inductance. These improvements achieved stable rotation of 0.015%

wow and flutter or less, which is considered to be the measurement

limit. Also, the thrust bearings supporting the heavyweight-class

platter use a special engineering plastic to provide both high rigidity

and reliability.

Suppressing Unwanted Motor Vibration

platform for the direct drive motor. The double coil, reinforced thrust

bearings, and a chassis with increased rigidity achieved a stabilised

motor with low centre of gravity. By positioning two stainless steel

weights with high rigidity and high specific gravity at the bottom of

the chassis, the rigidity and low centre of gravity are maintained.

These thorough measures to prevent unwanted vibration help to achieve

overwhelming rotary precision and improve S/N.

Heavyweight-class Turntable Platter

extremely high specific weight and are difficult to process, on the

outer periphery of a 10-mm-thick brass weight. The brass weight is

laminated onto the aluminium die-cast, giving the platter a total weight

of approximately 7.9 kg and an inertial mass of approximately 1 ton・cm.

A deadening rubber for eliminating unwanted vibration is also attached

to the rear surface to form a 3-layer construction and achieve high

rigidity and excellent vibration damping characteristics.

Separate Control Unit

effects of unwanted noise on the main unit. In order to achieve a power

supply circuit that provides good regulation for high torque, a

switching power supply is used. To reduce the noise reaching the pickup,

the switching power supply is equipped with a unique technology that

provides a voltage supply with minimal noise by a newly developed

“unwanted noise reduction circuit”. Also, to minimise the noise even

during communication, a highly reliable system that resists the effects

of external noise is used for communication between the main unit and

the control unit. These thorough noise-reduction measures achieve the

world’s highest-level S/N.

Minute Adjustment and Indication of Rotations

analogue records, but also SP (78 rpm). Rotation (rpm) can also be set

down to two decimal places (maximum ±16%) from the control unit. The

OLED display is also capable of displaying rotation with accuracy down

to two decimal places, so the user can both hear and see extremely

precise rotation.

High-sensitivity Tonearm

Technics has traditionally used the static balance, S-type universal

tonearm with a lightweight, high damping magnesium tonearm pipe. The

gimbal suspension construction tonearm uses high-precision bearings.

Highly skilled Japanese craftsmen handle all assembly and adjustment to

achieve a high initial-motion sensitivity to precisely trace the grooves

cut into the records. OFC is used for internal wiring, so the music

signal relayed from the cartridge is not dampened and the musical energy

cut into the record is not lost, thereby producing highly vivid sounds.

Tonearm Base

The tonearm base, to which the tonearm is mounted, is

strongly integrated with the turntable part. Comparing the turntable

base part with the tonearm mounting construction, the relationship of

the tonearm bearings, turntable bearings, and needle position is always

constant, providing a structure in which the vibration caused by the

rigidity of the turntable base materials has minimal effect, and the

tonearm performance is maximized. An optional tonearm base can also be

purchased, enabling, in addition to the standard tonearm, an existing

short or long-type tonearm from SME or Ortofon to be mounted (up to

three including the standard tonearm).

See more details for Sub tonearm base options

*Example of customisation

High-quality Terminal

select the desired PHONO cable. An integrated, machined, high-rigidity

aluminum housing also suppresses external noise from reaching the

pickup.

A Rigid Cabinet and High Damping Silicon Insulator

molding compound) and a 30-mm-thick aluminium top panel. The turntable

part is a 3-layer construction comprising BMC, aluminium die-cast, and a

25-mm-thick aluminium top panel. This gives the system a construction

of 5 layers of different materials to ensure sufficient rigidity. The

insulator that supports the cabinet is a special silicon rubber that

combines high vibration damping characteristics and long-term

reliability. Reinforcement with a cylindrical tube made of a microcell

polymer absorbs vibrations in the horizontal direction. These parts are

contained in a zinc die-cast housing with high specific gravity, for

isolation from external vibrations.

Turntable section

-

Drive Method

- Direct Drive

-

-

Motor

- Brushless DC motor

-

-

Turntable Speeds

- 33 1/3, 45, 78 rpm

-

-

Adjust Range

- ±16 %

-

-

Starting Torque

- 0.39 N・m / 4.0 kg・cm (3.47 lb-in)

-

-

Wow And Flutter

- 0.015 % W.R.M.S.

-

-

Turntable Platter

- Brass and aluminium diecast combined

Diameter : 323 mm (12-23/32″)

Weight : Approx. 7.9 kg (17.5 lbs) (including turntable mat)

-

Tonearm Section

-

Type

- Universal Static Balance

-

-

Effective Length

- From the tonearm pivot to the stylus : 254mm (10″)

From the tonearm pivot to the spindle : 239mm (9-13/32″)

-

-

Overhang

- 15 mm (19/32 inch)

-

-

Tracking Error Angle

- Within 1° 48′ (at the outer groove of 30 cm (12″) record)

Within 0° 30′ (at the inner groove of 30 cm (12″) record)

-

-

Offset Angle

- 21°

-

-

Arm Height Adjustment Range

- 0 – 15 mm

-

-

Stylus Pressure Adjustment Range

- 0 – 4 g (Direct Reading)

-

-

Applicable Cartridge Weight Range (including Headshell)

- 15.9 – 19.7 g (without auxiliary weight)

18.8 – 23.6 g (with small auxiliary weight)

22.5 – 26.3 g (with middle auxiliary weight)

26.0 – 31.0 g (with large auxiliary weight)

-

Terminals

-

Audio Output

- PHONO (Din Jack) x 1 *Straight Type Cable Only

-

General

-

Power Supply

- AC 110 – 240 V, 50 / 60 Hz

-

-

Power Consumption

- 10 W

Approx. 0.05 W (Standby)

-

-

Dimensions (W x H x D)

- Main Unit

531 x 188 x 399 mm (20-29/32 × 7-13/32 × 15-23/32 inch)

Control Unit

110 x 84 x 350 mm (4-11/32 × 3-5/16 × 13-25/32 inch)

-

-

Weight

- Main Unit Approx. 40.2 kg (88.7 lbs)

Control Unit Approx. 2.1 kg (4.7 lbs)

-

-

Operating Temperature Range

- 0° to +40° (32°F to +104°F)

-

-

Operating Humidity Range

- 35 % to 80 % RH (no condensation)

-

-

Accessories

- Turntable,

Turntable mat, EP record adaptor, Balance weight, Auxiliary

weight(Small)(Middle)(Large), Overhang gauge, Screw set for turntable,

Detachable handle, Hex wrench, Insulator attachment, Dust cover, AC main

leads, Owner’s manual

-

Reviews

There are no reviews yet.